Garage Door Component Categories

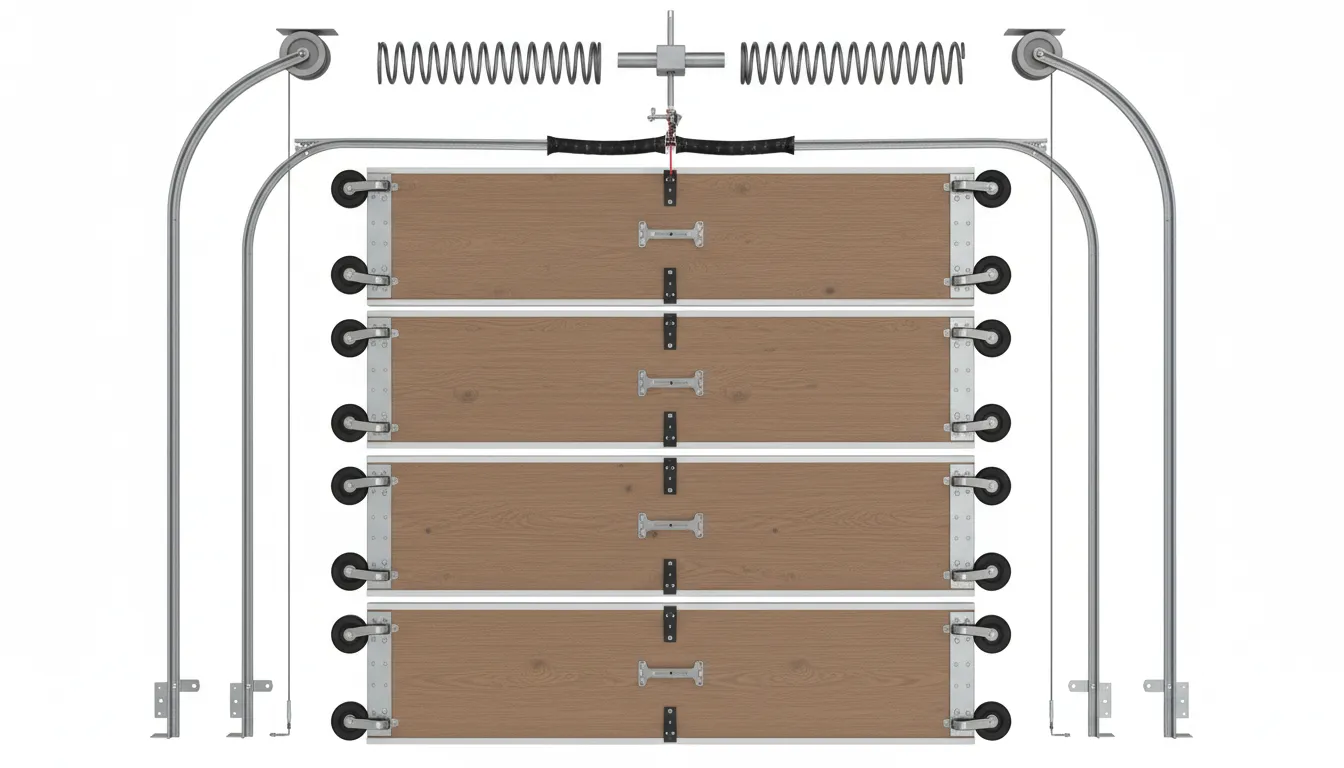

Springs & Counterbalance System

Mounted above the door on a steel shaft. Stores energy when wound and releases it to lift the door. Most residential doors use one or two springs rated for 10,000-20,000 cycles.

Mounted along horizontal tracks on both sides. Stretches as door closes, contracts to lift. Common on older or lighter doors. Always have safety cables running through them.

Steel tube that runs above the door holding the torsion springs. Connected to cable drums at each end. Transmits spring torque to lift cables evenly.

Grooved wheels at each end of torsion shaft. Cables wrap around them as door opens. Drum size determines lift ratio - wrong drums cause uneven lifting.

Track & Rail System

Metal channels on both sides of the door opening. Guide the rollers straight up during initial lift. Must be plumb (perfectly vertical) for smooth operation.

Run back into the garage parallel to ceiling. Support door weight when open. Should have slight downward slope toward back (about 1" per 8 feet) for proper closing.

Curved section connecting vertical to horizontal track. Standard radius is 12"-15". Low-headroom tracks have tighter curves for garages with limited ceiling clearance.

Metal brackets that attach tracks to the wall (flag) and ceiling (hanging). Proper positioning ensures track alignment. Loose brackets cause jerky operation.

Hardware & Movement Parts

Small wheels attached to hinges that ride inside tracks. Nylon rollers are quieter; steel rollers are more durable. Ball-bearing rollers reduce friction. Standard stem length is 2" or 4".

Connect door panels and hold rollers. Numbered by position - #1 at bottom, higher numbers toward top. Numbers are stamped on metal. Different offset for each position.

Steel cables running from bottom brackets, over cable drums, connected to spring system. They do the actual lifting of the door. Frayed cables can snap suddenly.

Heavy-duty brackets at bottom corners where cables attach. Under extreme tension from springs. NEVER attempt to remove or adjust - lethal spring force stored here.

Heavy metal plate mounted above door center. Anchors the stationary end of torsion springs and supports the torsion shaft. Must be securely bolted to header.

Opener System Components

Electric motor and drive mechanism housed in ceiling-mounted unit. Contains motor, circuit board, light sockets, and controls. Common brands: LiftMaster, Chamberlain, Genie.

Metal channel running from motor to door. Houses the chain, belt, or screw drive mechanism. Length must match garage depth. T-rail is strongest design.

Moves along the rail connecting opener to door. Inner trolley rides on chain/belt; outer trolley connects to door arm. Has quick-release for manual operation during power outages.

Two sensors mounted 4-6" above floor on each side. One sends invisible light beam, other receives it. If beam is broken, door reverses. Required by law since 1993.

Metal bracket bolted to top panel connecting door to trolley. Curved arm design prevents binding as door curves through track. Must be centered and secure.

Panels & Weatherstripping

Individual horizontal sections that make up the door. Usually 4-5 panels for standard 7' door. Made of steel, aluminum, wood, or composite. May have windows in top section.

Flexible rubber seal attached to bottom of door. Keeps out rain, snow, pests, and drafts. T-shaped or U-shaped to fit retainer channel. First seal to wear out.

Vinyl or rubber strips around door frame creating seal when closed. Compresses against door edge. Prevents drafts and improves energy efficiency. Often has nail-on flange.

Steel bars bolted horizontally across inside of top panel (and sometimes others). Prevents bowing and adds rigidity. Required for doors over 8' wide or with openers.

Parts Lifespan Reference

| Part | Average Lifespan | Visual |

|---|---|---|

| Bottom Seal | 2-5 years | |

| Weatherstripping | 3-7 years | |

| Extension Springs | 5-10 years | |

| Nylon Rollers | 5-10 years | |

| Torsion Springs | 7-12 years | |

| Lift Cables | 8-15 years | |

| Opener Motor | 10-15 years | |

| Steel Rollers | 10-15 years | |

| Hinges | 15-20 years | |

| Door Panels | 20-30 years | |

| Tracks | 25+ years |

⚠️ Dangerous Parts - Professional Only

- Torsion Springs: Store enough force to cause severe injury or death if released improperly

- Extension Springs: Can whip violently if they break without safety cables

- Bottom Brackets: Under full spring tension - NEVER loosen

- Lift Cables: Attached to spring system, under significant tension

- Cable Drums: Releasing winding can cause springs to unwind explosively

✓ DIY-Safe Parts & Repairs

Safe to Replace Yourself:

- Bottom seal / weatherstripping

- Side and top weatherstripping

- Rollers (with door secured down)

- Hinges (with door secured)

- Remote control batteries

Safe Maintenance Tasks:

- Lubricate springs, rollers, hinges

- Tighten loose track brackets

- Align safety sensors

- Test balance (with opener disconnected)

- Clean and adjust travel limits

Need Parts Replaced? We Can Help

We carry quality replacement parts for Toronto area homes. Call to identify what you need.