TorqueMaster springs (by Wayne Dalton) fail more frequently than standard torsion springs due to moisture buildup, limited sizing, and heat accumulation inside the tube. When your TorqueMaster breaks, you have two options: replace with another TorqueMaster ($300-$400) or convert to standard torsion springs ($400-$500). We recommend conversion for long-term savings and reliability.

If you have a Wayne Dalton garage door from the 1990s-2010s, you likely have their proprietary TorqueMaster spring system. While it looked sleek with the spring hidden inside a tube, many homeowners are frustrated by frequent failures and expensive replacements. This guide explains your options when your TorqueMaster spring breaks.

What is a TorqueMaster Spring System?

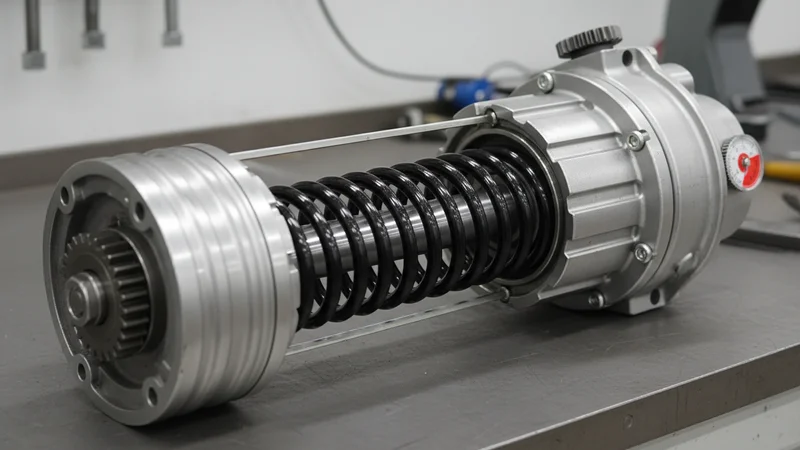

The TorqueMaster is Wayne Dalton's proprietary torsion spring system where the spring is enclosed inside a metal tube mounted above the garage door. Unlike standard exposed torsion springs that you can see, TorqueMaster springs are completely hidden from view. Tension is adjusted using a winding cone mechanism on one end of the tube. They were marketed as safer and more attractive, but have durability limitations.

Common TorqueMaster Problems

Moisture and Rust Buildup

The enclosed tube traps moisture that can't evaporate, leading to accelerated rust and corrosion on the spring. In humid climates or unheated garages, this is a major issue.

Limited Spring Sizes

TorqueMaster comes in fewer sizes than standard torsion springs. This often means using a spring that's not perfectly matched to your door weight, causing it to work harder and wear faster.

Heat Accumulation

The enclosed design doesn't dissipate heat well. Each cycle generates friction heat that builds up inside the tube, weakening the metal over time.

Proprietary Parts

TorqueMaster uses non-standard parts that not every technician stocks. This can mean longer wait times for repairs and higher parts costs.

Shorter Lifespan

While standard torsion springs typically last 7-10 years, TorqueMaster springs often fail at 5-7 years - meaning more frequent replacement costs.

Difficult Inspection

You can't visually inspect an enclosed spring for wear signs. With standard springs, you can spot rust, gaps, or stretching before failure.

Signs Your TorqueMaster is Failing

Because you can't see the spring inside the TorqueMaster tube, you need to recognize other warning signs before complete failure. Watch for these indicators:

Audible Warning Signs

- Unusual grinding or scraping: The spring may be rubbing against the tube interior, indicating wear or rust buildup

- Loud bang when operating: Springs stretching beyond normal limits or coils separating

- Clicking sounds: The winding mechanism may be slipping or worn

- Increased vibration: Spring balance degrading, causing uneven tension

Visual Warning Signs

- Door doesn't stay in place: When you open the door halfway and release, it should stay put—this is called the balance test. If it drifts up or down, the spring is losing tension

- Door opens slowly or unevenly: One side of the door rising faster than the other indicates spring problems

- Rust stains near the tube: Moisture is escaping from the tube, meaning corrosion is likely occurring inside

- Gap in the door panels: Uneven spring tension can cause panels to separate slightly

Operational Warning Signs

- Door feels heavy to lift manually: The spring is no longer counterbalancing the door weight properly

- Opener strains to lift door: Motor works harder, runs longer, or makes straining sounds

- Door slams down when closing: Loss of controlled descent indicates significant spring wear

- Cables appear loose or slack: Spring tension affects cable tautness

⚠️ Warning

If you notice any of these signs, avoid operating the door until it's inspected. A failing TorqueMaster can break suddenly, potentially damaging your door or causing injury.

Your Two Options When TorqueMaster Fails

Our Recommendation: Convert to Standard Torsion

For most homeowners, conversion pays for itself over time. You'll spend $100 more upfront but save $300-$400 on the next replacement. Plus, you'll have more repair options and longer-lasting springs.

TorqueMaster vs Standard Torsion: Side-by-Side

| Feature | TorqueMaster | Standard Torsion |

|---|---|---|

| Average Lifespan | 5-7 years | 7-10+ years |

| Replacement Cost | $300-$400 | $160-$280 |

| Parts Availability | Limited, proprietary | Universal, widely available |

| Technician Availability | Specialized only | Any garage door tech |

| Visual Inspection | Not possible | Easy to check condition |

| High-Cycle Option | Not available | 25,000-50,000 cycles available |

| Aesthetics | Cleaner, hidden | Visible spring |

What Does Conversion Involve?

Converting from TorqueMaster to standard torsion involves:

- Removing the TorqueMaster tube - The entire assembly is taken down

- Installing torsion hardware - New spring anchor bracket, drums, and bearing plates

- Mounting properly-sized springs - Matched specifically to your door weight

- Adjusting tension and balance - Fine-tuned for smooth operation

- Testing and safety check - Ensuring proper opener integration

The conversion takes about 1.5-2 hours and your door will operate exactly as before - just with a more reliable spring system.

When Does TorqueMaster Replacement Make Sense?

There are situations where sticking with TorqueMaster might be appropriate:

- You're selling the home soon - Conversion may not provide value you'll recoup

- Aesthetics are critical - You strongly prefer the hidden spring look

- Budget is tight right now - TorqueMaster replacement costs less upfront

- Spring failed unusually early - May be a one-time issue worth replacing

TorqueMaster History and Why It's Being Phased Out

Wayne Dalton introduced the TorqueMaster system in the early 1990s as a safety-focused alternative to exposed torsion springs. The concept was sound: by enclosing the spring inside a tube, homeowners wouldn't be exposed to the spring if it broke. Marketing emphasized the "cleaner look" and "safer design."

For about 15 years, TorqueMaster was the standard spring system on most Wayne Dalton residential doors. However, as more doors reached the end of their spring life, the problems became apparent:

- High warranty claims: Springs failed earlier than expected, leading to customer complaints

- Repair difficulties: Independent technicians couldn't easily service the proprietary system

- Customer frustration: The hidden design that was meant to be a selling point became a liability when repairs were needed

- Parts availability: As fewer doors were sold with TorqueMaster, parts became scarcer

By the mid-2010s, Wayne Dalton began transitioning away from TorqueMaster on new installations. Today, most new Wayne Dalton doors use standard torsion spring systems - a tacit acknowledgment that the traditional design works better for most applications.

Safety Warnings for TorqueMaster Systems

TorqueMaster spring repair is not a DIY project. While the enclosed design was marketed as "safer," the reality is that TorqueMaster repair is more dangerous than standard torsion spring repair for several reasons:

Why TorqueMaster DIY is Dangerous

- Hidden tension: You cannot see how much tension is in the spring, unlike exposed torsion springs where you can count coils

- Specialized tools required: TorqueMaster winding requires specific tools not available at hardware stores

- Improper technique: The winding mechanism operates differently than standard springs, and incorrect technique can cause the spring to release violently

- Lack of visual confirmation: You can't verify that tension is properly released before working on the system

Always Call a Professional When:

- The door won't open or is extremely heavy

- You hear unusual sounds from the spring tube

- The door slams down instead of closing gently

- You need any adjustment to the spring tension

- You're considering conversion to standard torsion

⚠️ Critical Safety Notice

Garage door springs are under extreme tension and can cause serious injury or death if handled improperly. TorqueMaster systems contain approximately 200+ pounds of stored energy. Never attempt to repair, adjust, or remove a TorqueMaster spring system without professional training and equipment.

TorqueMaster Service Pricing

Compare your options for TorqueMaster repair vs conversion:

| Service | Price Range (+ tax) | Includes |

|---|---|---|

| TorqueMaster Replacement | $300 - $400 | New TorqueMaster spring, installation, testing |

| Convert to Standard Torsion | $480+ | Remove TorqueMaster, install standard system, warranty |

| Standard Torsion (Single) | $160 - $220 | Spring, installation, balancing (for converted systems) |

| Standard Torsion (Both) | $280 - $400 | Both springs, matching, warranty (for converted systems) |